The electric vehicles, with their batteries, have undergone rapid changes in their evolutionary process over the past ten years. For an individual traveling for purchase or mere curiosity about the engineering of a battery, one of the most common questions is: How much does an electric car battery weigh? In 2025, with further advancement in EV technology, the answer will be much more complex. Below, we talk about average weights, the battery types’ discrepancies, and why weight is essential in this respect for performance, efficiency, and sustainability.

Why Battery Weight Matters in EVs?

Battery weight is essential in the design and performance of EVs. Usually, the battery pack is the heaviest single component in an electric vehicle, whereby the weight affects driving range, acceleration and handling, weight distribution, charging time, and vehicle efficiency.

Knowing the weight of these batteries is very important for consumers as well as the manufacturers, as the industry begins to target lightweight, energy-dense battery technologies.

How Heavy Can an Electric Car Battery Be, in 2025?

So, how much does an electric car battery weigh nowadays?

As of 2025, the average weight of an EV battery pack ranges from 900 to 1,200 pounds (about 400 to 545 kg). But this could vary greatly, depending on the size of the vehicle, the capacity of the battery (in kWh), and the chemistry of the battery.

Here is somewhat of a classification for typical battery weights by types of vehicles:

| EV Type | Battery Size (kWh) | Approximate Battery Weight (lbs.) |

| Small City EV | 20-30 kWh | 300-500 lbs. |

| Compact/Mid-size Sedan | 50-70 kWh | 700-1,000 lbs. |

| Electric SUV | 80-100 kWh | 1,000-1,300 lbs. |

| Electric Pickup Truck | 120-200+ kWh | 1,500-2,900 lbs. |

Battery weight is directly related to capacity: the larger a battery pack (in kWh), the more energy it stores, and the heavier it becomes.

Average Battery Weight for Popular EV Models

To further illustrate the subject, here’s a weight comparison of batteries for popular EVs in 2025:

| Model | Battery Capacity (kWh) | Battery Weight (lbs.) |

| Nissan Leaf | 40 | ~650 |

| Hyundai Ioniq 5 | 77.4 | ~925 |

| Ford Mustang Mach-E | 91 | 1,050 |

| Rivian R1T (Pickup Truck) | 135 | 1,800 |

| Lucid Air | 112 | 1,200 |

So, you see, on average, the battery-grade weight depends on the size and performance expectations of the vehicle.

What Does a Tesla Battery Weigh?

It is a common question among electric vehicle buyers. Tesla is well known for producing automobiles with larger battery packs, especially in the premium segment.

Here is some information regarding Tesla vehicles:

| Tesla Model | Battery Size (kWh) | Battery Weight (lbs.) |

| Tesla Model 3 Standard | 60 | 1,060 |

| Tesla Model Y Long Range | 75 | 1,200 |

| Tesla Model S Plaid | 100 | 1,200-1,300 |

| Tesla Cybertruck AWD | 120-200 kWh | 2,000-2,900 |

Although battery technology is on the cutting edge for energy density, heavyweight remains a major disadvantage since they have to be so large to enable performance.

How Much Would a Lithium Battery Weigh?

Lithium-ion batteries are a standard in the electric vehicle battery industry, but how much does a lithium battery weigh per kWh?

Approximately:

One kWh of lithium-ion battery capacity weighs 15–20 lbs. (6.8–9.1 kg).

Which means:

Normally, a 60-kWh battery is in the range of 900-1,200 pounds.

A 100-kWh battery can be a 2,000-pound piece, depending upon the chemistry and packaging.

It is pertinent to mention here that solid-state lithium batteries, expected to be pursued more by the late 2020s, promise not only higher energy density but also lower weight for the battery for a given range.

Why Are EV Batteries So Heavy?

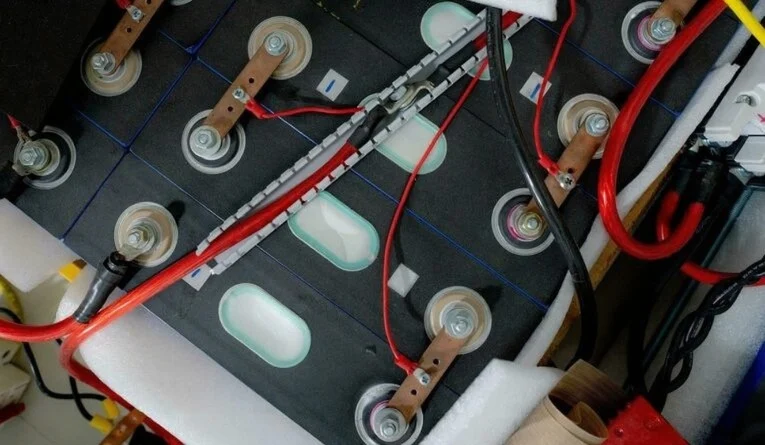

EV batteries are complex structures whose functioning depends on thousands of individual cells interconnected with the cooling and protective casing. Here is the reason behind their huge weight:

- Battery cells: These are tiny structures teased into a few thousand. A Tesla Model S battery is composed of over 7,000 cells.

- Battery management system (BMS): Manages charging, temperature, and safety.

- Cooling system: Liquid cooling adds weight but is needed to keep battery performance and life high.

- Reinforced casing: It is packed in a very robust, crash-safe casing, bolted to the undercarriage of the car.

A combination of these materials reduces safety, driving performance, and wear, thus adding significant weight.

Does Battery Weight Affect EV Performance?

Yes, battery weight directly influences the performance:

- Acceleration: Faster gets slightly slower with weight; however, in a way, high torque in modern EVs offsets it.

- Range: Need more power to drag heavier batteries farther distances, hence compromised efficiency.

- Braking and Handling: Heavier vehicles imply longer stopping distances but also have the advantage of a low center of gravity, thanks to battery placement.

- Tire Wear: Heavier loads would increase tire wear and suspension stress over time.

However, EV manufacturers are continually working on designs to properly balance and distribute weight with battery packs anchored low into the chassis.

Weight vs. Range: Is Bigger Always Better?

More capacity, more weight—but does a heavier EV mean good? Not always.

While big batteries do provide range, they also:

- Increase cost

- Pressure efficiency

- Longer to charge

- Greater stress on suspension, tire, and so on

And so, considering all these factors, right-sizing battery packs based on real-world driving patterns started to appear as a new design trend. Manufacturers such as Hyundai, Volkswagen, and even Tesla are looking into modular battery platforms wherein battery capacity can be scaled down or up depending on what the customer wants.

Can Lighter EV Batteries Become Standard?

All thanks to R&D, the answer is “yes”—eventually. In a breakthrough in 2025 and beyond:

- Solid-state batteries: Supposedly, these will be 30-50% lighter for the same energy output since they use solids for electrolytes instead of liquids.

- Lithium-silicon and lithium-metal chemistries: Being tested to enhance energy densities and reduce weights.

- Battery packaging innovations: Cell-to-pack and cell-to-chassis designs make for weight reduction through the elimination of redundant structures. This means lighter, smaller bats with the same or larger range than bulkier packs at present.

How Manufacturers Offset Battery Weight?

- EV makers employ a plethora of counteracting measures against heavy batteries:

- Lightweight Materials: Aluminum, carbon fiber, and high-strength steel reduce weight.

- Regenerative Braking: In energy regeneration, when braking, it replenishes range, which is being drained, while keeping extra battery skins away.

- Aerodynamic-Optimized Bodies: Reduced drag coefficient means less energy consumption.

- Suspension Tuned: Air suspensions are adaptive to coordinate the extra weight, while components are reinforced.

The basic objective is to ensure that all sectors of performance, safety, and efficiency are not compromised due to the bulk of the battery pack.

Battery Recycling and Sustainability Considerations

As EV adoption proceeds at a skyrocketing rate, interest too arises as to what happens to the batteries at the end of their lifespan. With the weight and complexity of these batteries, there are unique aspects involved in environmental recycling and sustainability. Commonly referred to as an EV battery, it contains valuable materials like lithium, cobalt, nickel, and manganese, which are recoverable and reusable.

Nowadays, in 2025, the technology to recycle has gained so much traction that over 90% of all critical minerals can be reclaimed from spent batteries. Redwood Materials and Li-Cycle spearhead the innovation by developing closed-loop recycling systems to minimize the dependency on newly mined materials. The reuse of batteries is garnering attention; for example, some EV batteries are repurposed for use in stationary storage in homes or businesses once their storage capacity falls short of what is required for EV performance.

The weight of the battery offers some difficulty in removal and transport, yet the streamlining of recycling processes cuts down on inefficiency and environmental burden. Lighter modular systems will be developed in the near future, as battery architecture continues to evolve, allowing simple disassembly and recycling, thereby alleviating the entire process of EV sustainability. Understanding this full lifecycle is what will be required to determine the long-term effect of the weight of EV batteries on environmental and resource consumption.

Conclusion

How much does an electric car battery weigh? The answer really depends on the car, battery size, and chemistry. On average, EV battery packs weigh between 900 and 1,200 pounds, but big ones can almost hit 3,000 pounds.

Thinking about battery weight is essential when weighing range, performance, and charging in your decision. Heavier batteries will be around until 2025, but with solid-state technologies and efficient material engineering, lighter ones will soon arrive.

If you are about to buy an electric vehicle, or even if you are just interested in the setup behind it, having some knowledge related to how battery weight affects your vehicle is essential for an owner.