We believe in complete control over quality and performance. That’s why our core manufacturing process is housed under one roof in Apopka, FL. From custom component installation to final quality assurance checks, our team ensures each unit meets the highest standards before it leaves the floor.

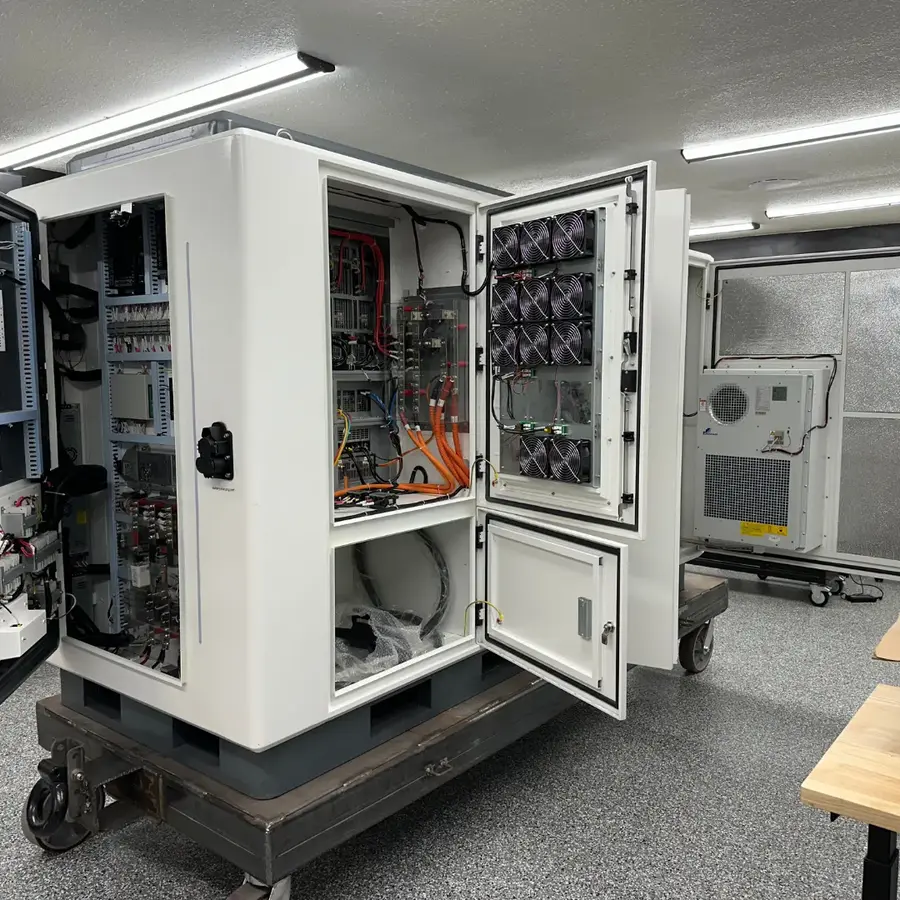

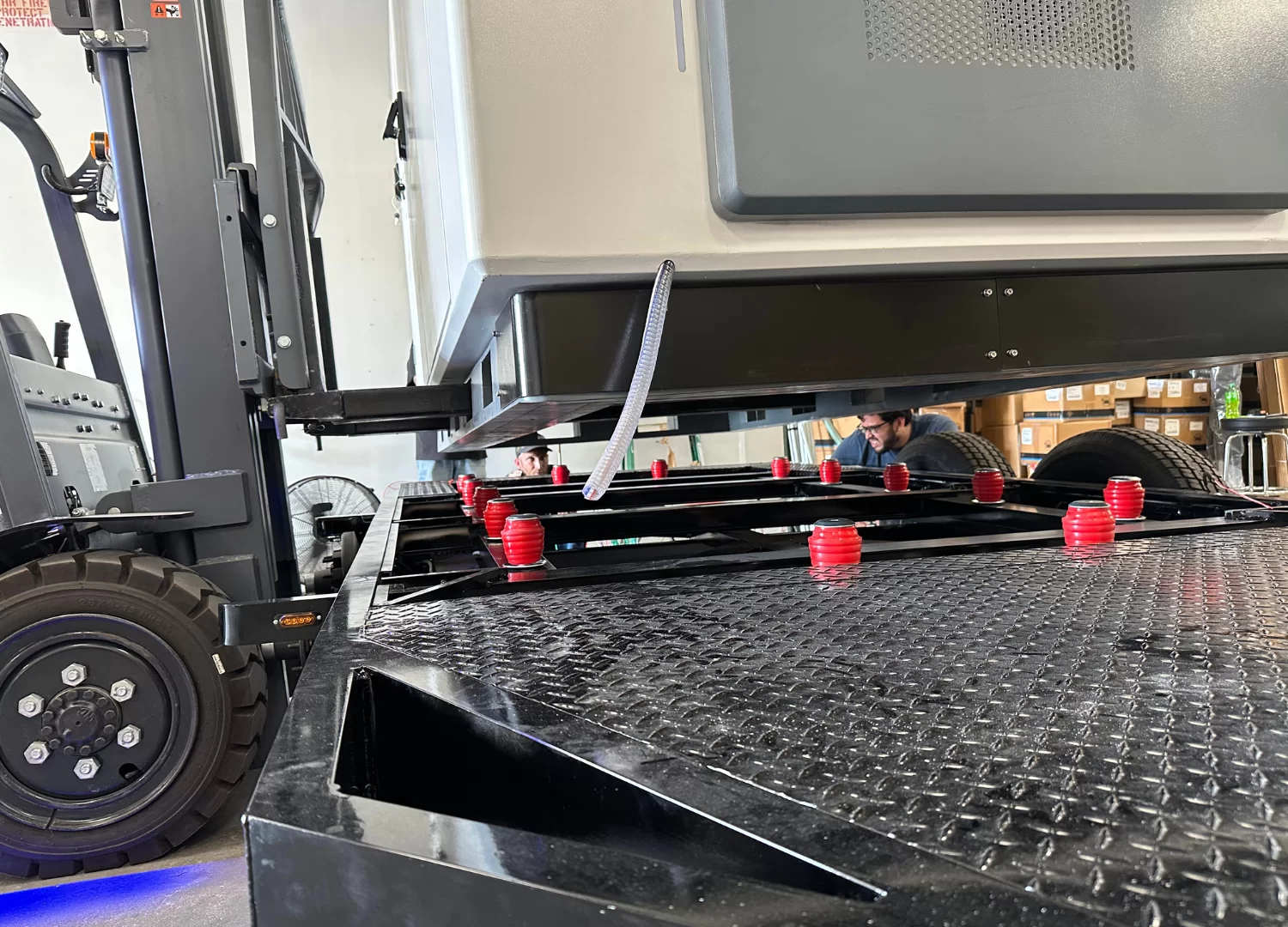

Here’s what it really means to manufacture our produts in-house. Each unit goes through a meticulous, multi-stage build process – from internal wiring and metal fabrication to testing under real-world loads. Our engineers and technicians bring unmatched attention to detail and pride in every weld and wire.

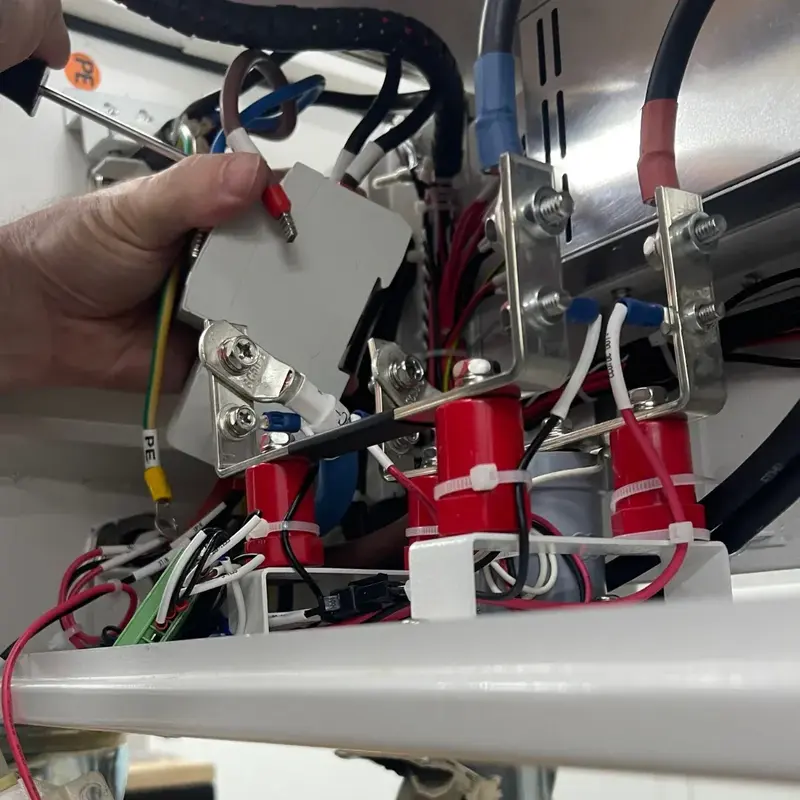

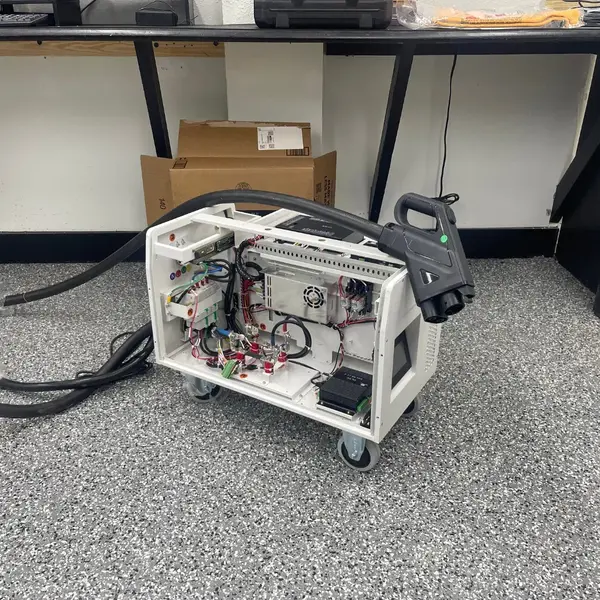

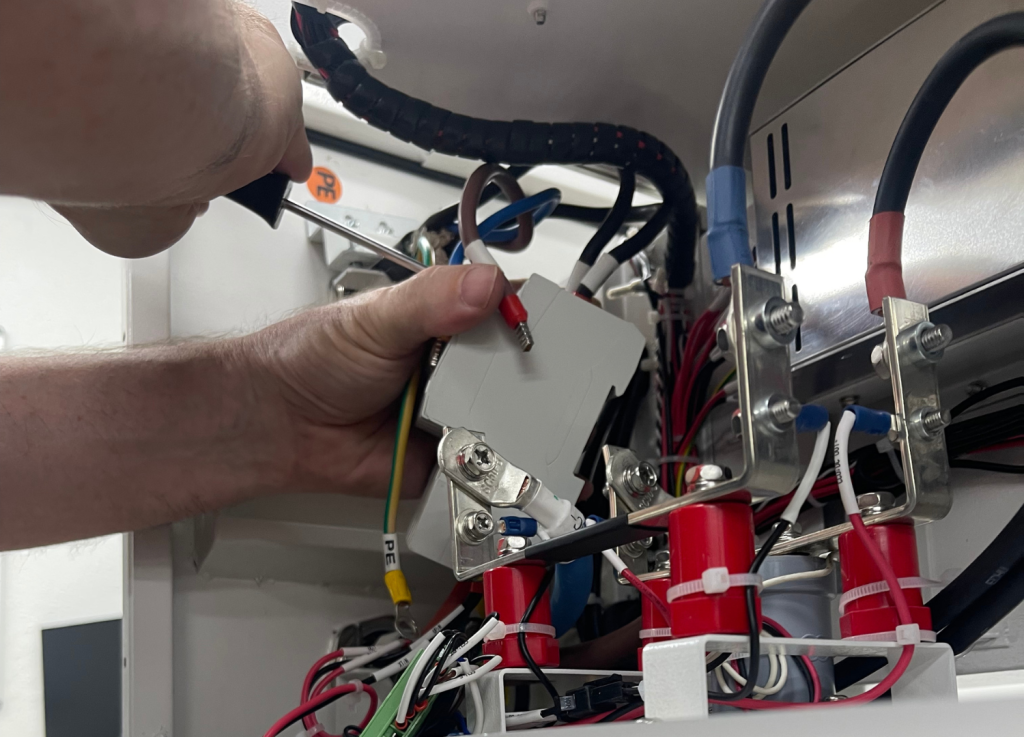

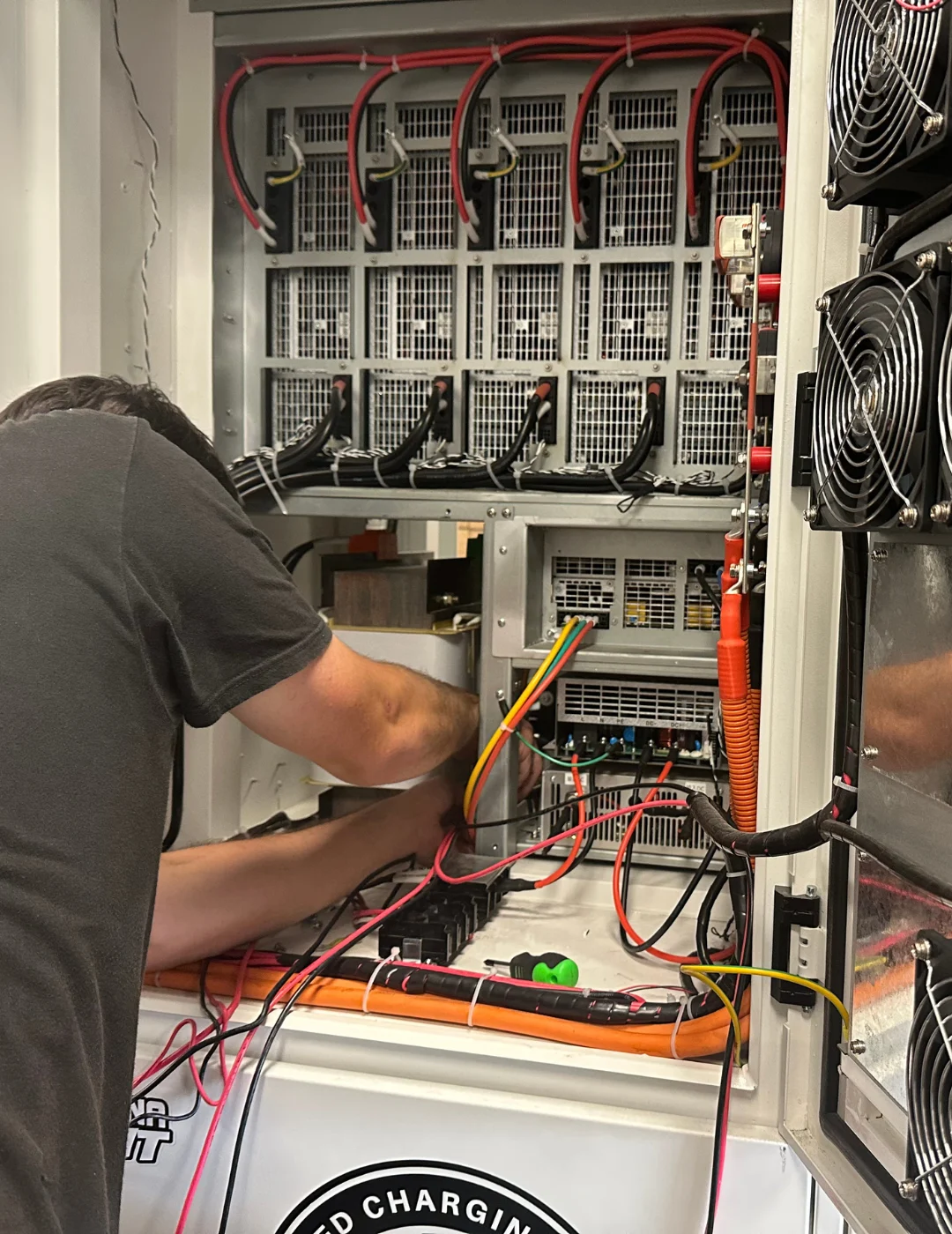

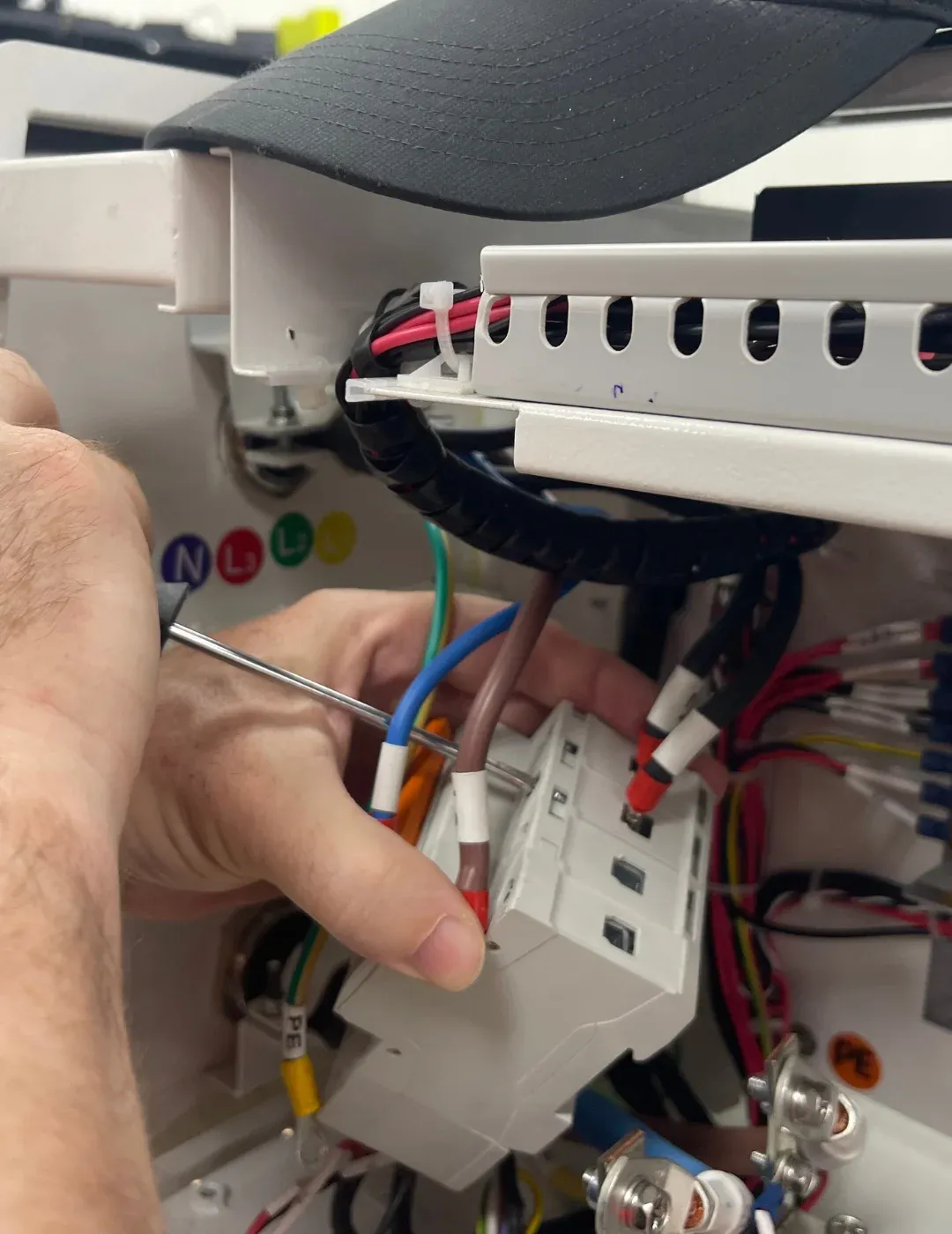

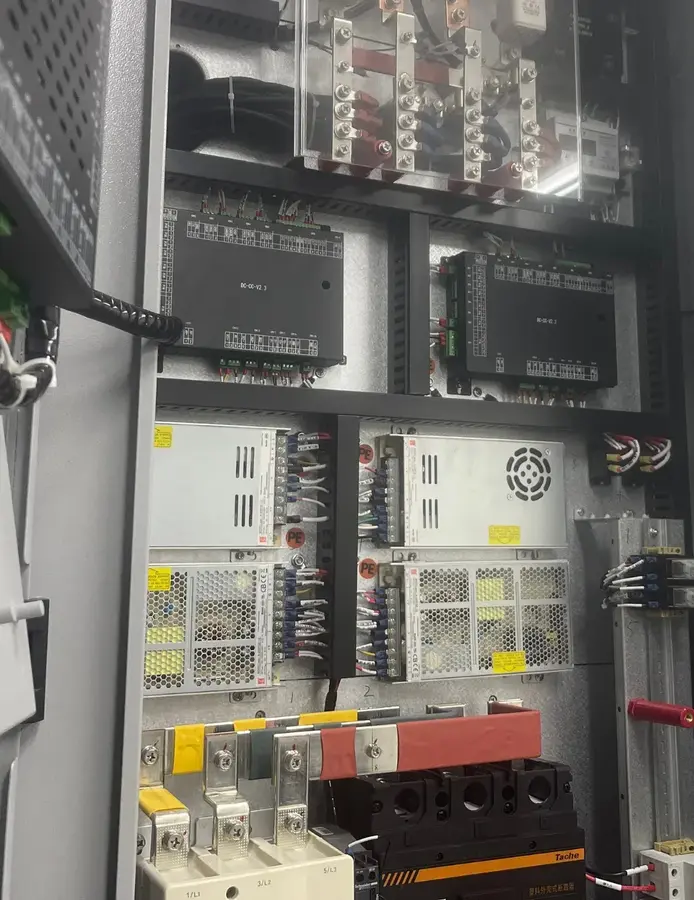

Every unit begins with precise integration of critical internal components, including high-voltage wiring, power distribution systems, and control modules. Our technicians ensure each element is installed to exact specifications, forming the foundation of a reliable charging system.

Before moving forward, each unit undergoes multiple quality assurance checkpoints. From voltage regulation to internal cooling systems, we test real-world functionality under load to ensure consistent, safe operation in demanding environments.

Our software team loads the latest firmware onsite, enabling smart charging features, system monitoring, and seamless diagnostics. After installation, every unit is run through internal diagnostics to confirm firmware

With all systems go, the unit receives final paneling, branding, and labeling. Each charger is thoroughly reviewed and certified by our team for delivery. We don’t ship it unless we’re confident it will perform reliably in the field.

Owning our process means faster turnaround times, better quality control, and the flexibility to innovate without waiting on outside vendors. For our dealer network, that means responsive support, tailored solutions, and the confidence that every product is backed by the people who made it.

We design, build, and test every unit ourselves. This means full control over quality, timelines, and performance.

Because everything happens under one roof, we can implement design or performance updates quickly, often within days, not months.

Our team is based in Florida and ready to support you. From technical help to product updates, you’re always dealing with people who know the equipment inside and out.

We don’t rely on outsourced assembly lines. Our team builds each unit with precision and pride, so when you sell a Charge Rigs product, you know exactly where it came from.